Our technology services for manufacturing industry

Our smart software solutions for modern manufacturers

Business Operations

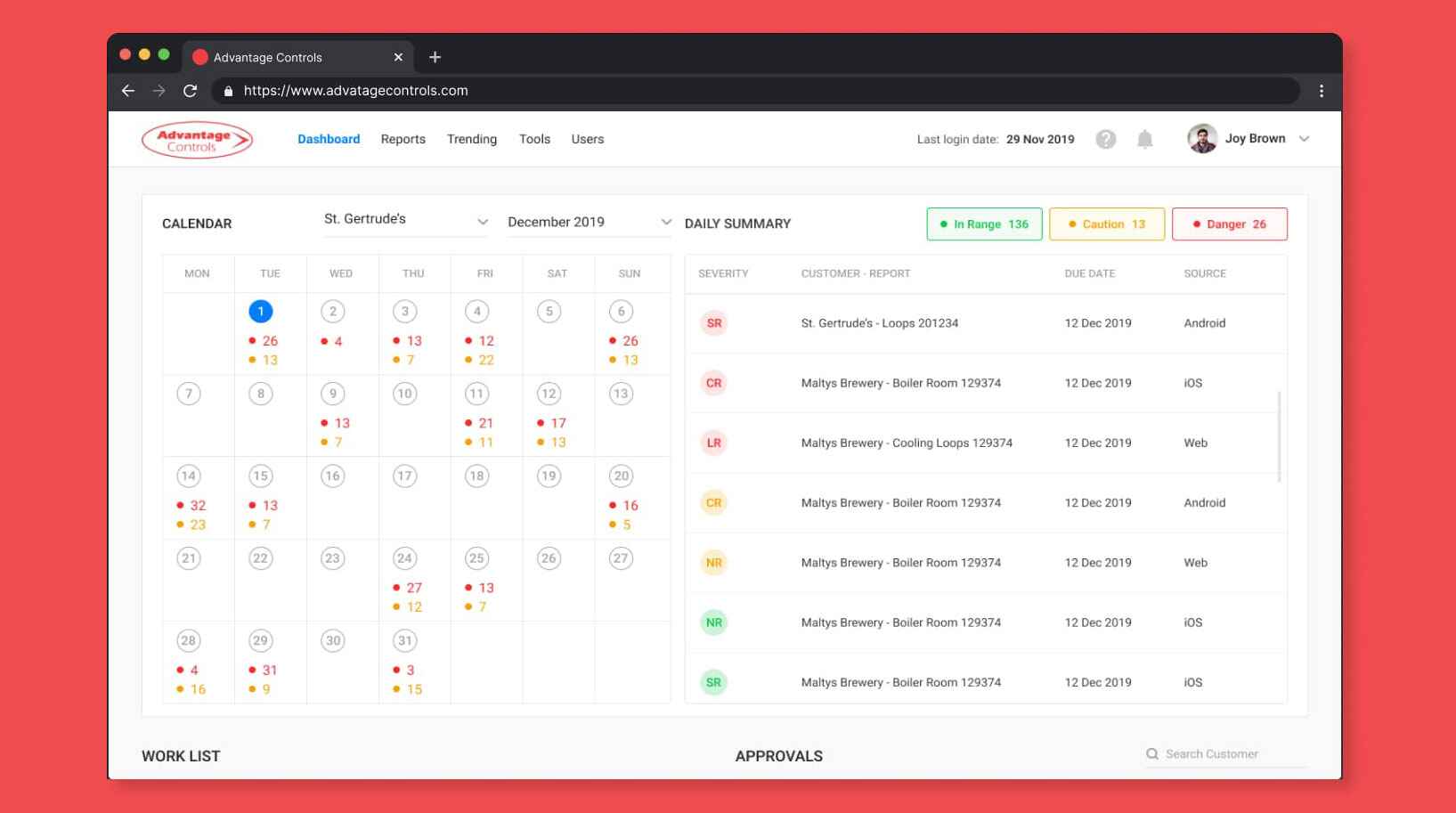

From ERP and HR systems to document workflows and business intelligence dashboards – we centralize your operational data, automate approvals, and bring clarity to day-to-day decisions.

Production Processes

We modernize your production stack with AI-supported planning tools, MES systems, and condition monitoring software that improve output quality, reduce downtime, and give you real-time production visibility.

Smart Factory

We help you transition to smart manufacturing with IoT integrations, HMI development, and agentic automation that enables predictive maintenance, machine-level analytics, and shop floor optimization.

Vendor Management

Build stronger, more accountable supplier networks with vendor portals, procurement automation, and real-time dashboards for tracking compliance, delivery performance, and pricing trends.

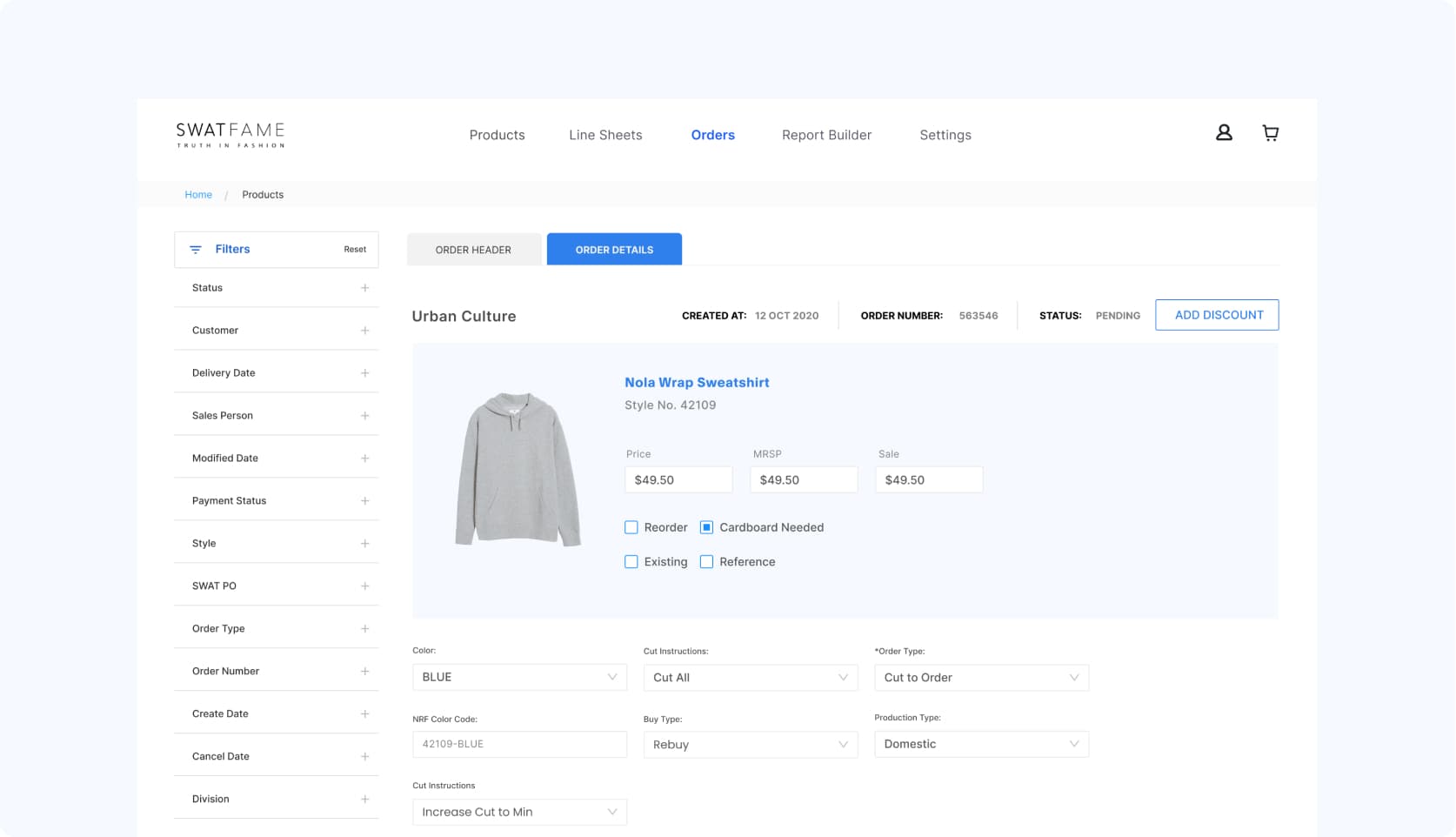

Sales & Customer Management

From custom CRMs to order-tracking portals, we digitize your sales and service cycles – enabling faster response times, better forecasting, and a smoother customer experience end to end.

Field Service Operations

We create mobile-first tools for your on-site teams – whether that’s equipment maintenance, quality audits, or installation tracking – giving them access to checklists, data, and reporting in real time.

How we implement industry 4.0 technologies

Industry 4.0 marks a technological shift for manufacturers. By embedding state-of-the-art technologies into your core processes, we help you move from reactive to predictive, from manual to intelligent, and from fragmented to fully connected.

Here are some of the technologies we use to make that transformation real:

Benefits of Industry 4.0 technology solutions for manufacturing

Embrace Industry 4.0 through systems that are practical, scalable, and tailored to real operational needs.

Connected Systems Across the Business

We integrate your ERP, MES, inventory, and planning tools so that information flows across departments – helping teams align faster and make fewer mistakes.

AI and Agentic Automation

From predictive maintenance to real-time production adjustments, we bring in AI and agentic systems that take initiative, make decisions, and keep things moving without constant supervision.

Data That Drives Decisions

We build dashboards that turn raw production data into real-time insights, so you can see bottlenecks, delays, or inefficiencies – and fix them before they grow.

Smart Tools for Smarter Workflows

Whether it’s document handling, shift scheduling, or quality tracking – we digitize and automate everyday processes to reduce friction and free up your team.

Scalable Infrastructure

Industry 4.0 is about preparing for the future. We modernize your systems with scalable architecture that adapts as your operations grow – without the need to rebuild everything from scratch.

What sets us apart in the manufacturing space

We help manufacturers #digitizeworkflows, #optimizeproduction, and #improvesupplychains with custom-built, scalable software solutions.

Get in Touchmanufacturing plants empowered with digital solutions

client retention rate

years serving the manufacturing industry

certified ensuring secure and reliable systems

Discovery & Operations Mapping

We start by understanding your unique production workflows — from inventory and procurement to shop floor control and distribution. Our team works closely with plant managers, ERP admins, and operations leads to identify process gaps, manual dependencies, and data silos.

System Architecture & Compliance Planning

Whether you’re dealing with ISO standards, OSHA reporting, or industry-specific regulations, we embed compliance into the system design from day one. We architect secure, modular systems that support traceability, quality assurance, and long-term scalability.

Interface Design for Industrial Workflows

From machine operators to logistics coordinators, we design intuitive dashboards and interfaces that reduce training time and eliminate process errors. Prototypes are validated against real-world tasks to ensure usability in high-pressure manufacturing environments.

Agile Development & Systems Integration

We develop in iterative sprints, ensuring your software aligns with the realities of production timelines. Our solutions integrate with MES, SCADA, PLCs, and ERP systems like SAP, Oracle, and Microsoft Dynamics — creating a unified tech ecosystem that actually talks to each other.

Testing, QA, & Environment Simulation

We rigorously test for real-world readiness — including uptime resilience, device compatibility, latency under load, and quality tracking accuracy. This ensures the platform works as expected in live production, not just in theory.

Deployment with Zero Downtime Disruption

We deploy during planned production windows, ensuring smooth transitions with minimal operational downtime. This includes phased rollouts, system handover, data migration, and team training to keep your lines moving while the tech evolves.

Continuous Monitoring, Support & Optimization

Post-launch, we provide performance monitoring, issue resolution, and feature scaling. Whether you’re expanding to a new plant, integrating new machinery, or evolving reporting needs, we’re your long-term technology partner for digital manufacturing transformation.

Why work with Code District?

Candid conversations, clear vision

We believe in open communication. We'll work with you to understand your unique challenges and goals, fostering collaboration and a clear roadmap for your transformation journey.

Industry knowledge & foresight

Our team boasts in-depth experience across various industries. We leverage this knowledge to anticipate your needs, propose cutting-edge solutions, and tailor strategies that drive business impact.

Expertise rooted in practice

We're not just theorists. Our team has a proven track record of successful tech implementations. You'll benefit from practical solutions backed by real-world experience.

Diverse talent pool & scalability

Our cross-disciplinary experts enable us to build the perfect team for your project. As your needs evolve, we seamlessly scale our resources to match them.

Global security & quality standards

Keeping your data and operations secure is paramount. We adhere to the highest international security and quality standards, ensuring peace of mind throughout the modernization process.

FAQs

What’s the average cost of a manufacturing software project?

Costs vary based on the system—whether it’s MES, ERP integration, or production analytics. As a manufacturing software development company, we tailor each project to your factory size, workflow needs, and digital maturity.

How long does it take to develop a custom manufacturing platform?

Most custom builds take between 8 to 14 weeks. We follow an agile development model to ensure that mission-critical features are delivered and tested early.

Can your software integrate with our legacy ERP or SCADA systems?

Yes. Integration is our strong suit. We’ve connected custom solutions with SAP, Oracle, Dynamics, and shop-floor control systems to create unified manufacturing workflows.

Do you offer support and upgrades post-deployment?

Absolutely. We provide full post-launch support—from real-time monitoring to adding new modules as your production or compliance needs evolve.

Can your solutions help us with predictive maintenance and real-time visibility?

Yes. Our manufacturing software uses IoT and AI to detect anomalies, schedule maintenance, and provide live dashboards—empowering data-driven decisions on the floor.

Share your business goals with technical experts

Sales and general inquires

sales@codedistrict.comCall us

+1 (703) 940-1971“Code District successfully launched our application on time. The team worked hard, adjusted to our schedule, and ensured our requests were turned around very quickly. They asked the right questions, used sound judgment, and made consistent progress, demonstrating strong technical skills and a driven attitude.”