Breaking the Threads of Legacy - SwatFame’s Digital Evolution

SwatFame, a California-based apparel manufacturer renowned for its denim and casual wear, sought to modernize its legacy systems. With a commitment to delivering high-quality apparel and staying ahead of market trends, SwatFame needed a digital transformation to streamline processes and improve operational efficiency.

40% reduction in order processing time

25% decrease in operational costs

California, United States

Apparel & Manufacturing

November 2020 to Present

Services Used

“ Code District has been great to work with and always wants to do things the right way. In some cases, we have had to change our own design, and they are really helpful in completing our needs and making sure the integrity of the software is on point. They have been very professional and easy to work with.”

IT Director, Swatfame

The Challenge

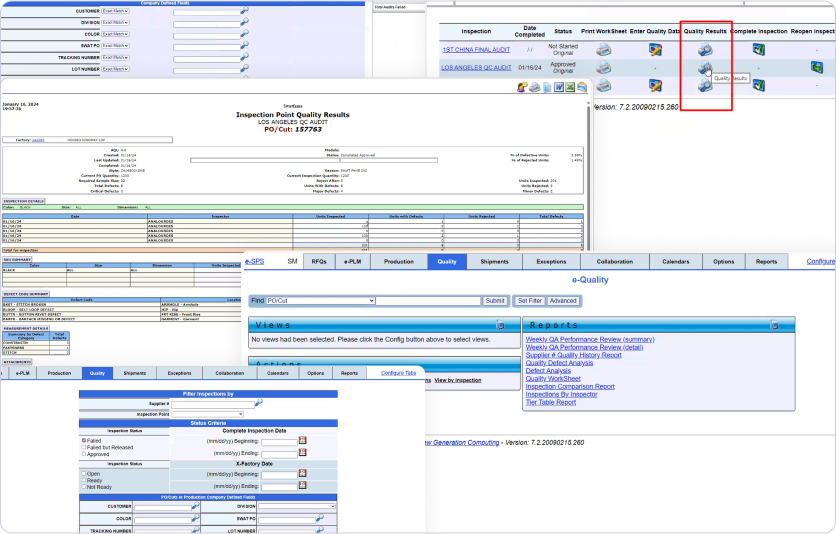

SwatFame relied on multiple disconnected systems to manage its design, order processing, and inventory workflows. This fragmentation created inefficiencies and slowed operations. Below are the key challenges SwatFame faced:

-

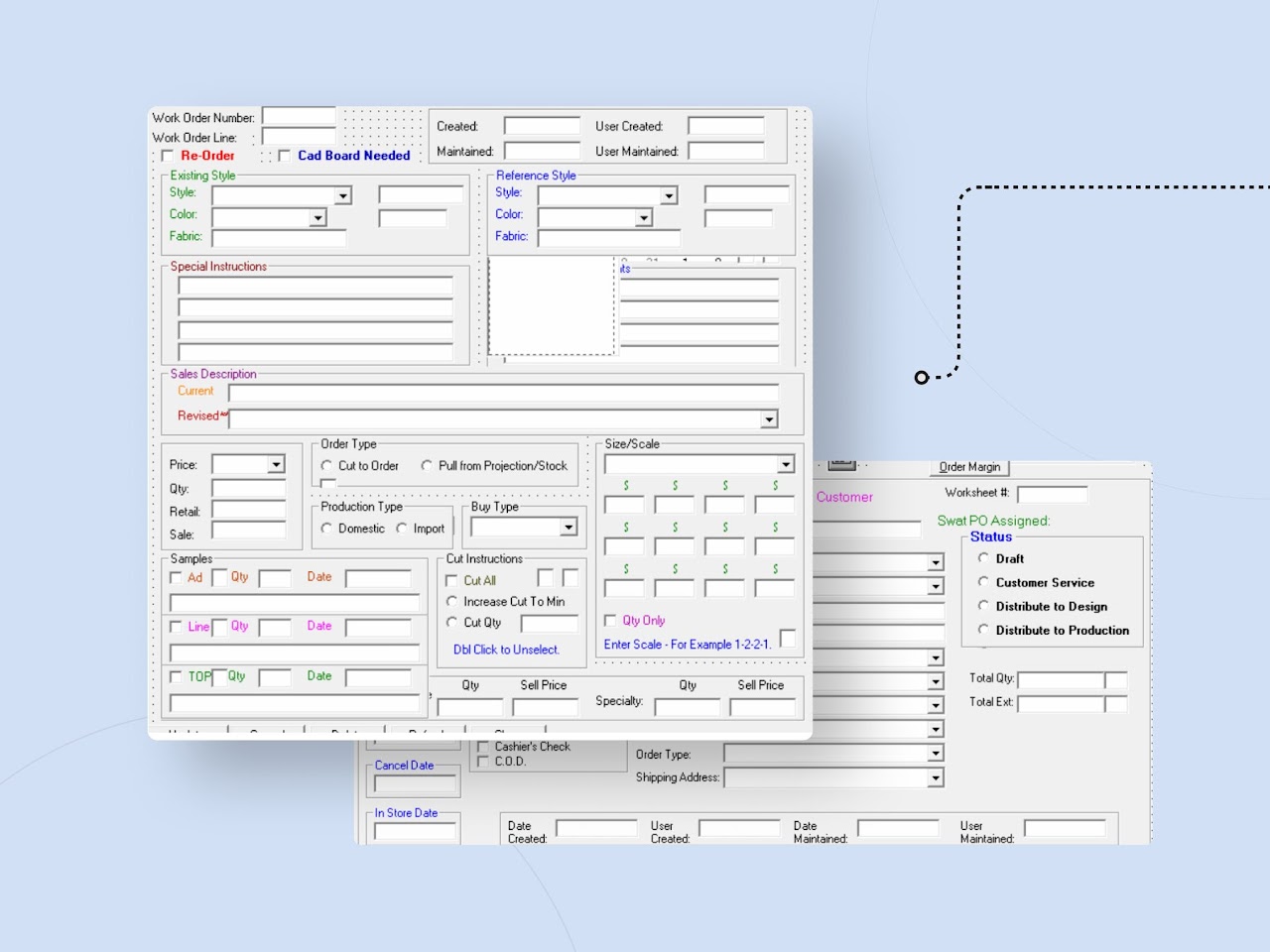

Disconnected Systems

SwatFame's core workflows were divided across legacy systems like VB6-based Worksheet Entry and GDTS for order processing, AS400 for ERP, and Picture Planner for catalog generation. The lack of integration forced teams to manually transfer data between systems, leading to errors and delays.

-

Inefficient Database Management

The outdated database schema resulted in redundant and poorly linked data, complicating inventory management and decision-making processes.

-

Poor Scalability

The legacy systems couldn't scale to support increasing client demands or large-scale production workflows, limiting the company’s growth potential.

-

Limited Collaboration

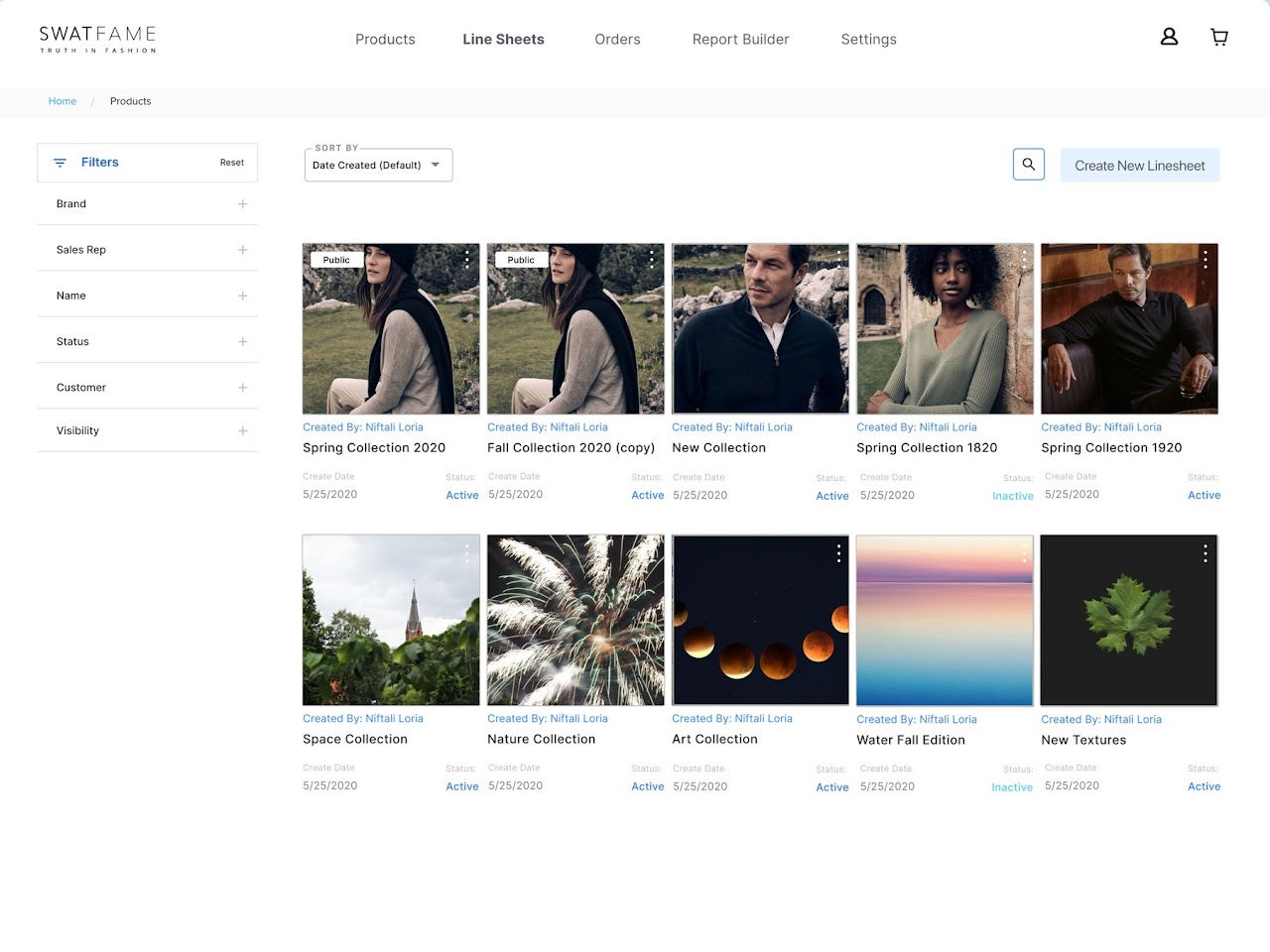

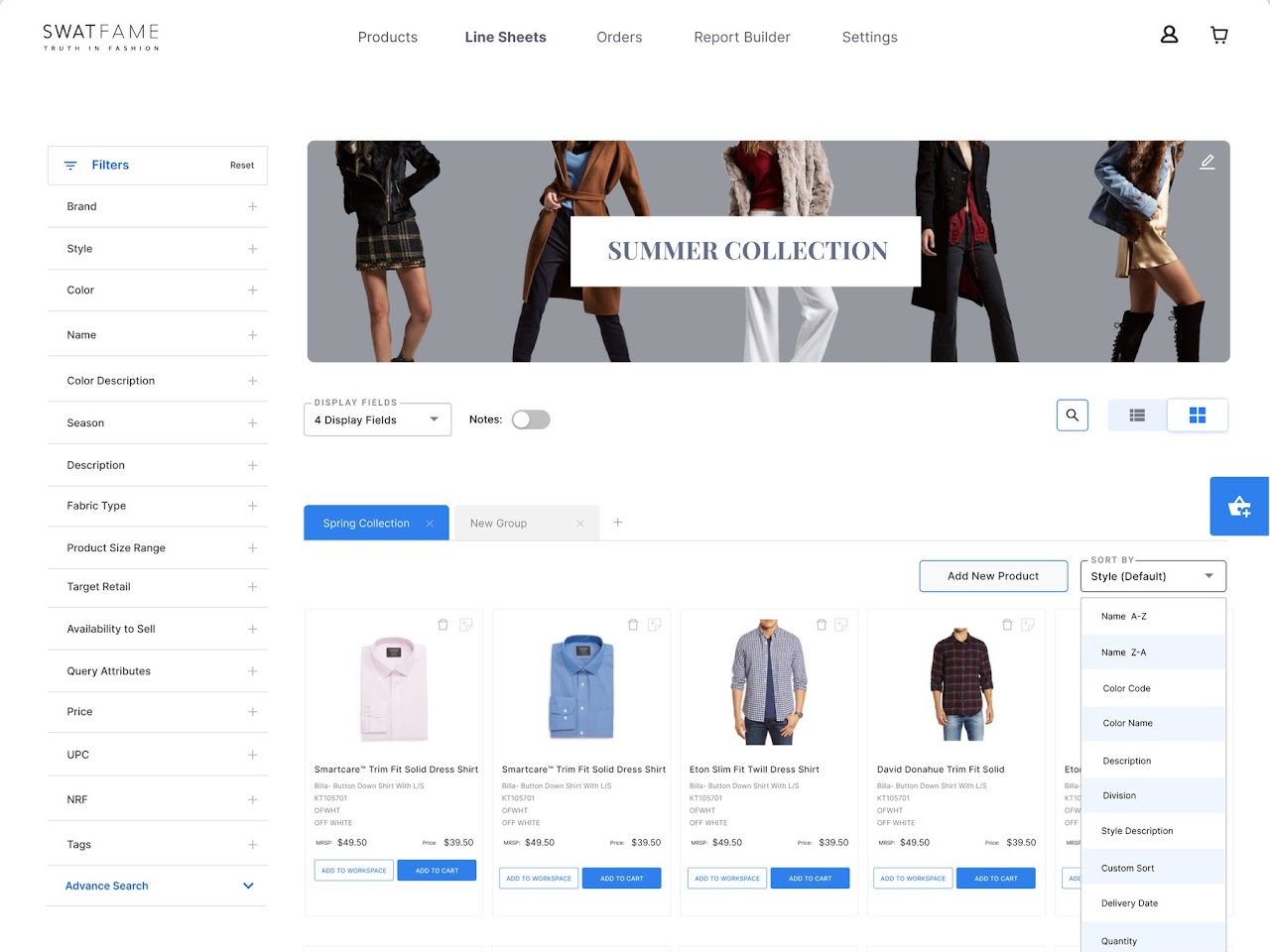

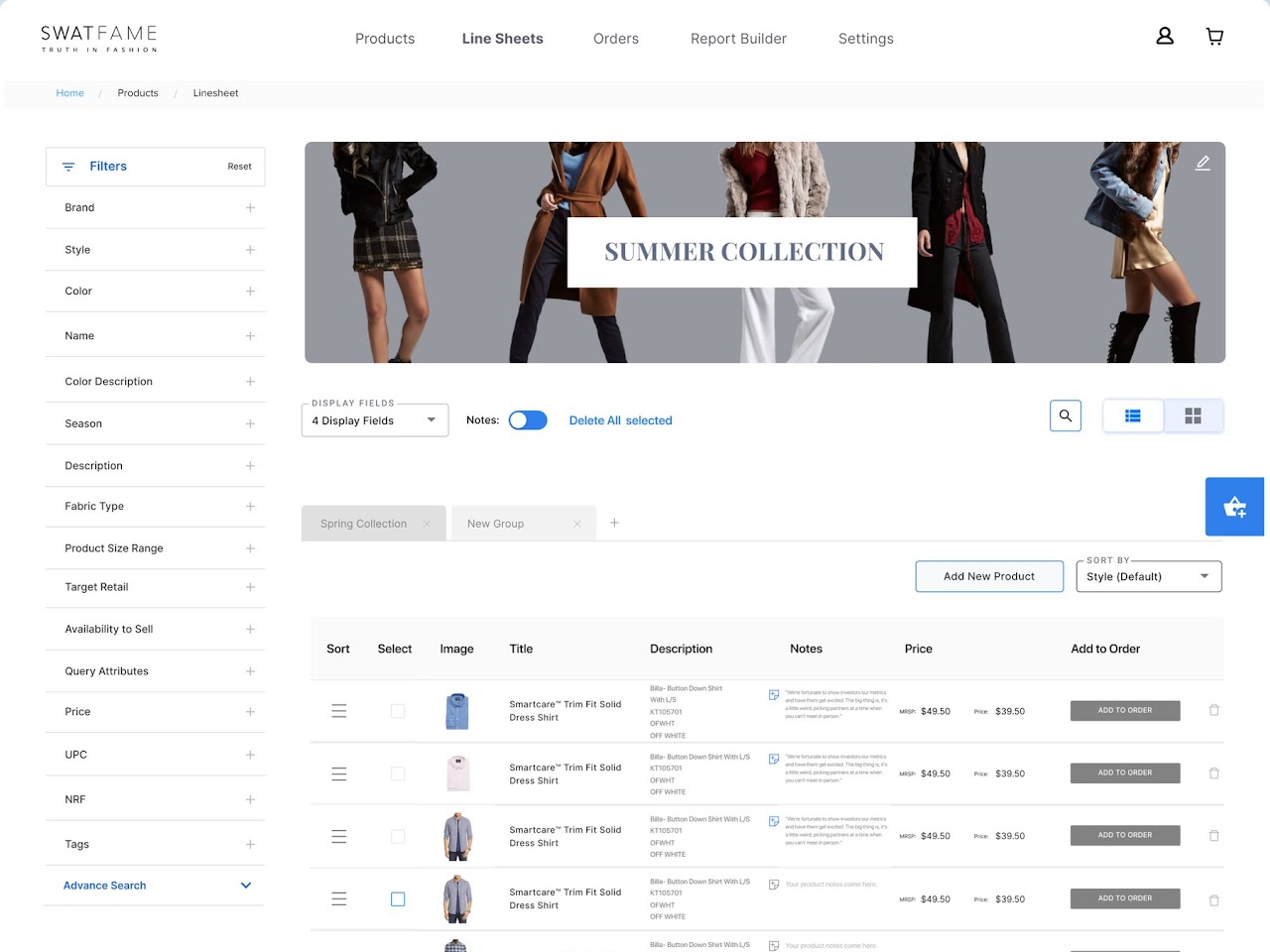

Siloed data and disjointed processes hindered collaboration between departments, slowing decision-making and reducing overall productivity. Sales teams had to manually generate reports and client catalogs, which were time-intensive and prone to errors.

Our Solution

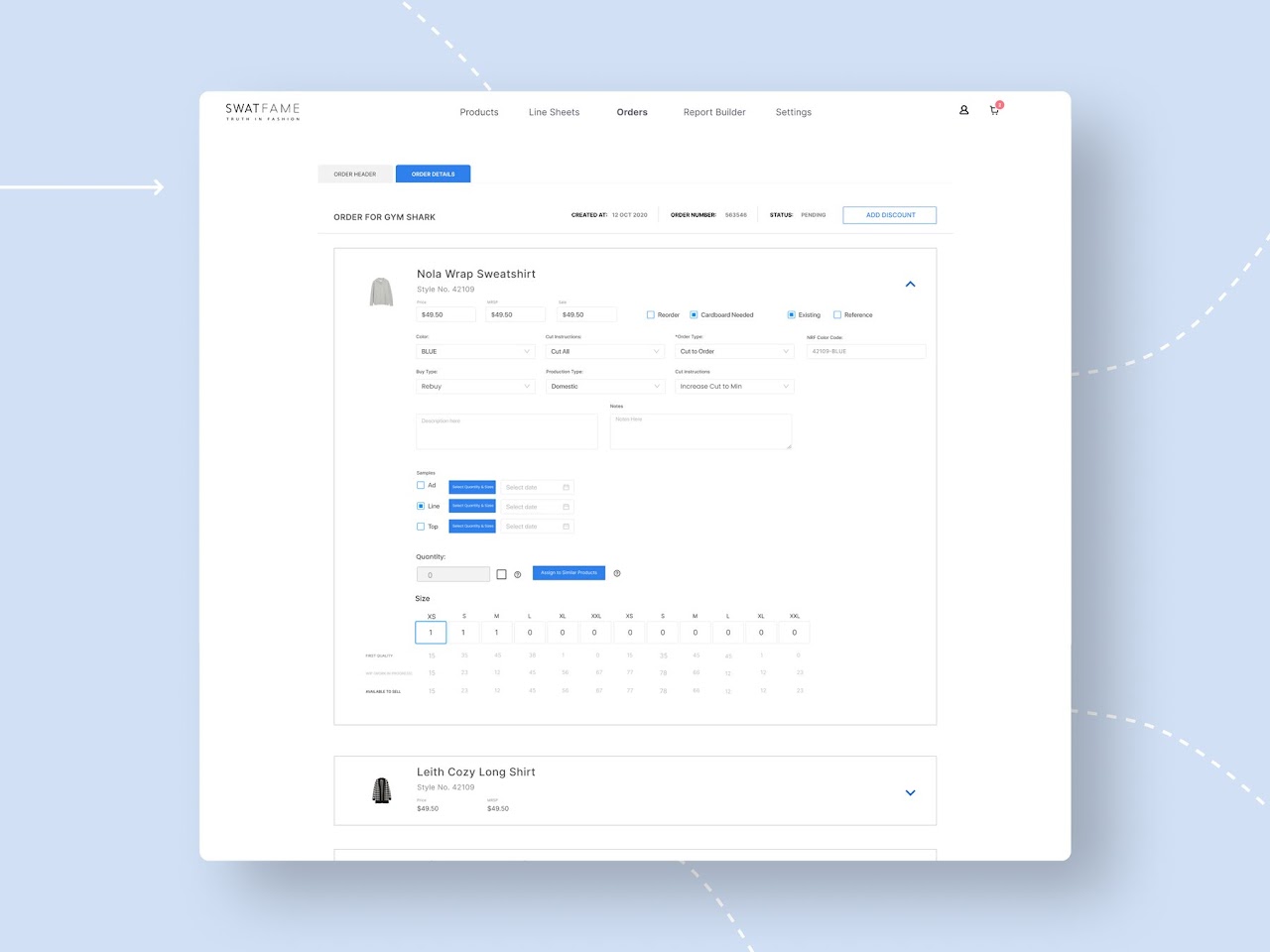

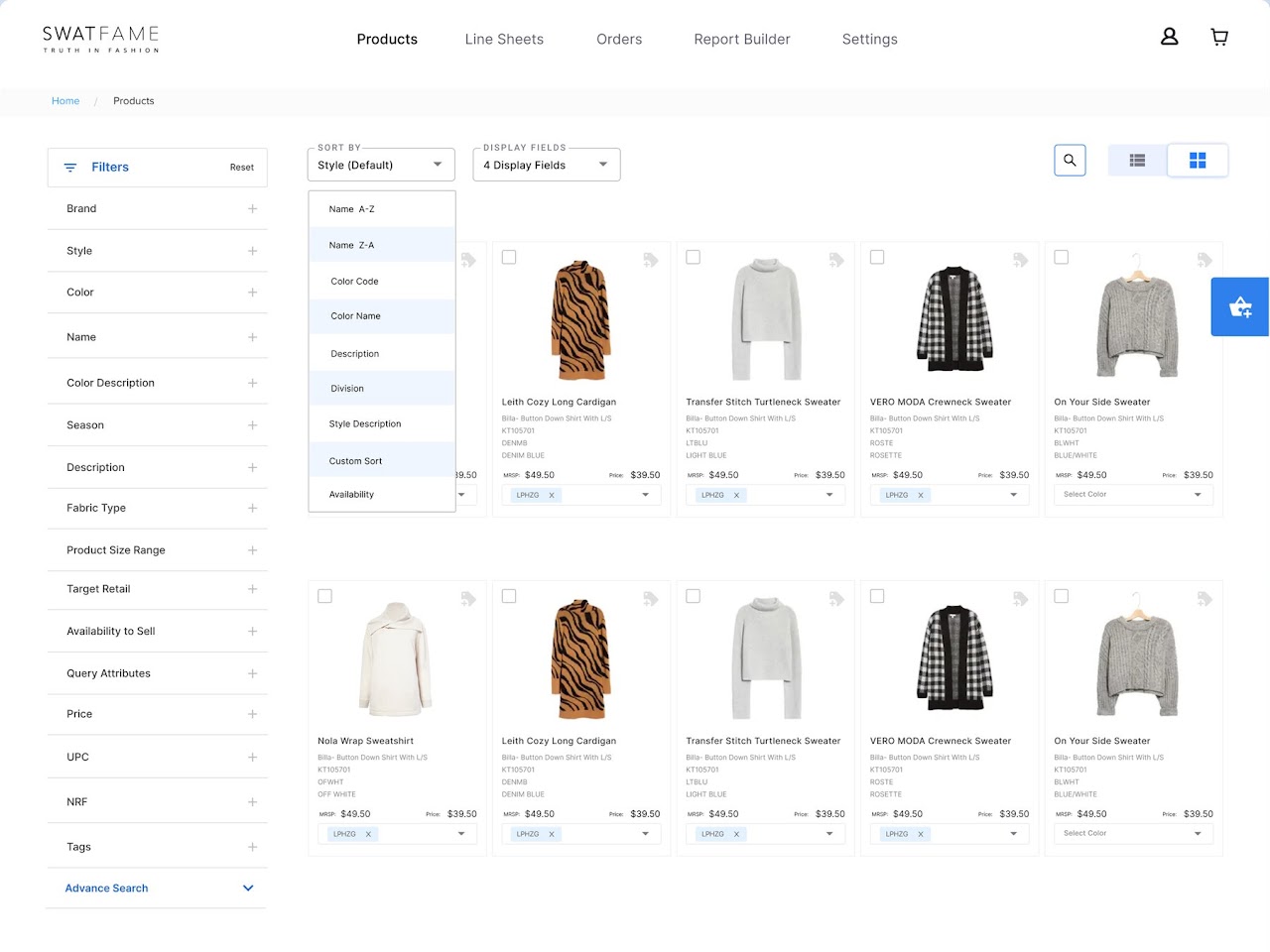

SwatFame partnered with our team to modernize its legacy systems, focusing on creating a centralized, scalable web-based system that met their operational needs. Here's how we addressed their challenges:

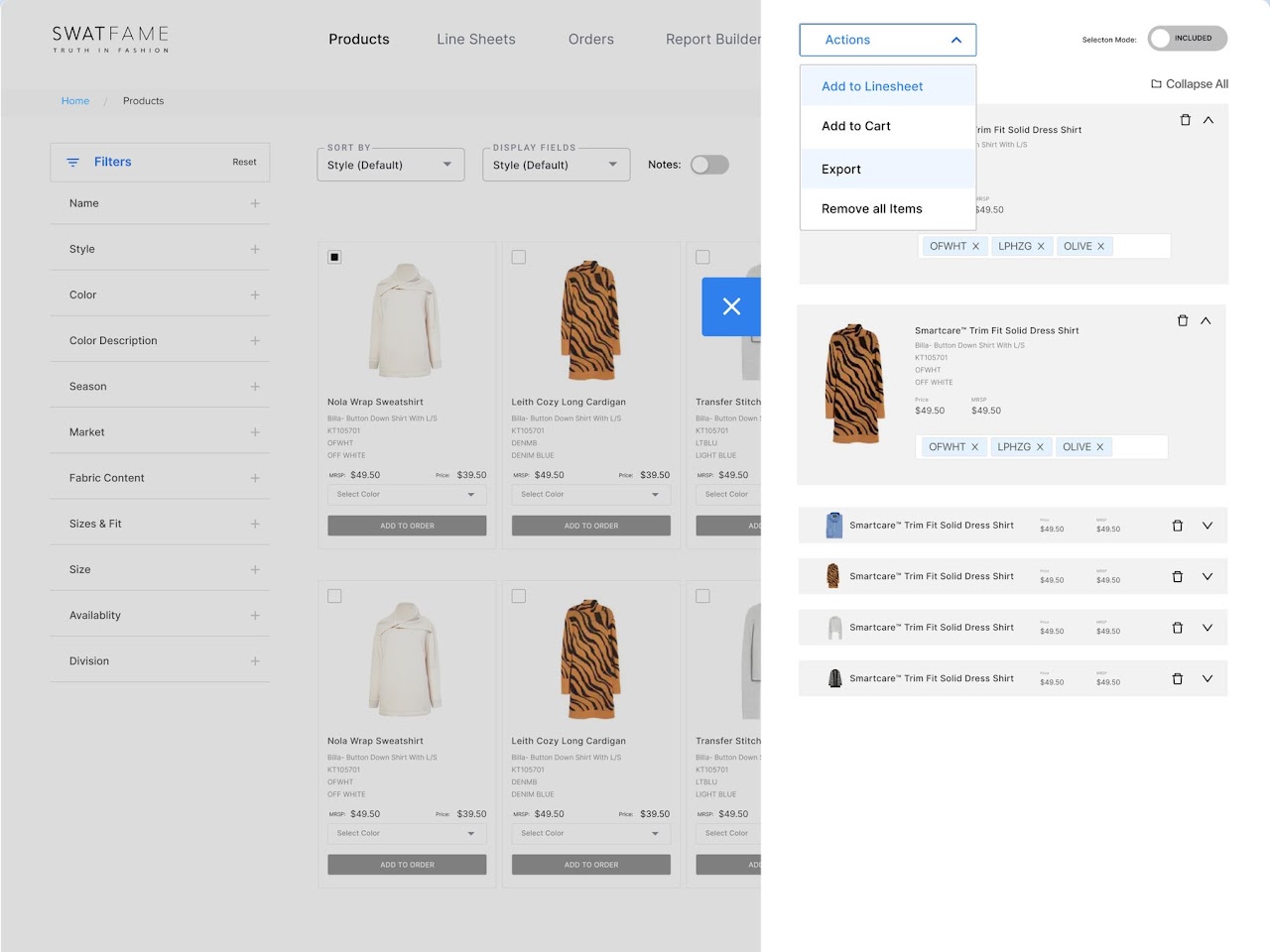

Get the full case studyUnified Order Processing Platform

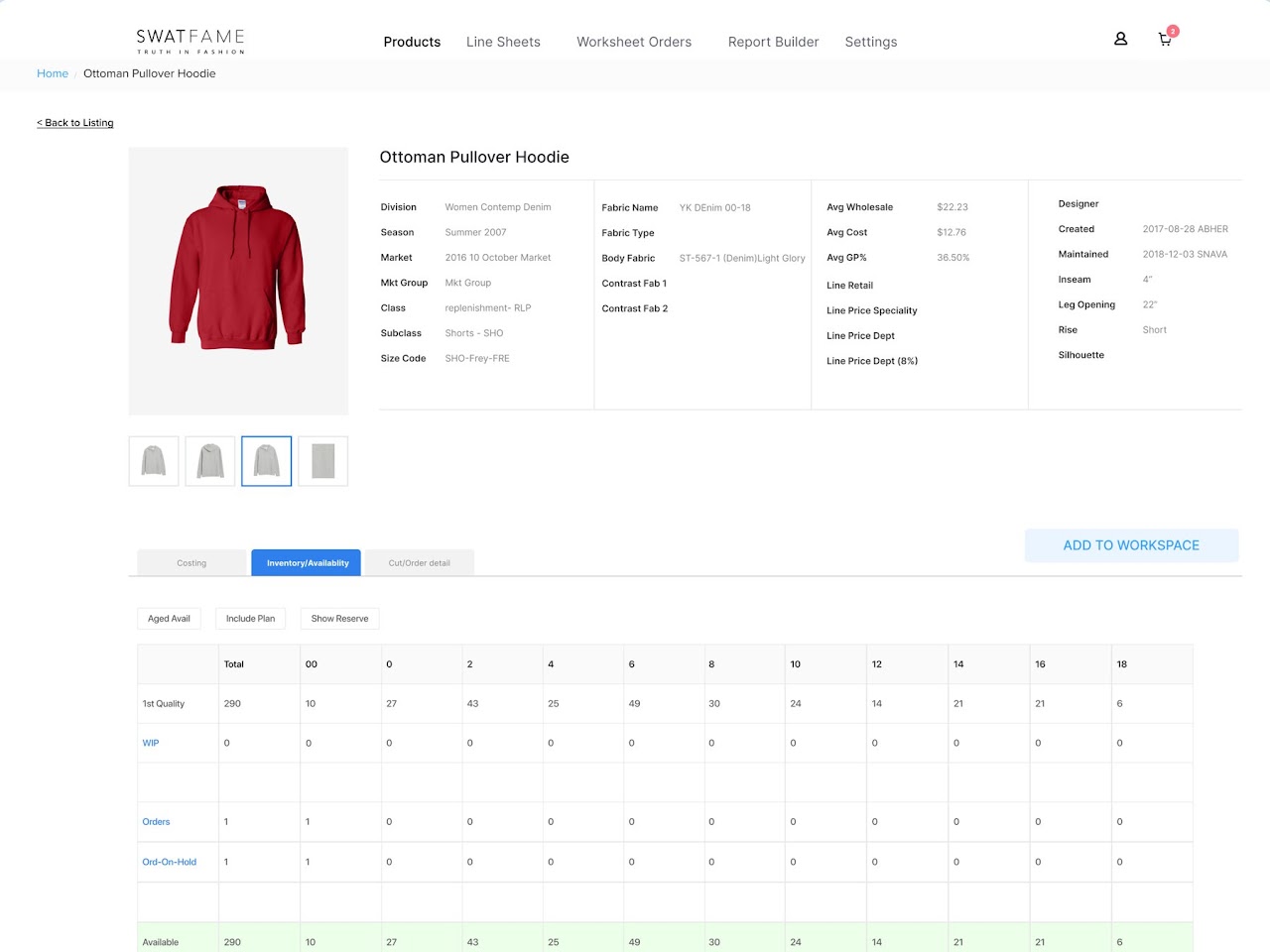

We consolidated two fragmented systems into a comprehensive Order Entry (OE) system and replaced the outdated technology of the Garment Design Tracking System (GDTS) system with a single platform.

Centralized Asset Management

A robust PLM (Process Lifecycle Management) system was developed to unify design workflows. Designers could manage components, BOMs, and assets like images and documents from a single platform, improving efficiency.

Enhanced Productivity

The centralized system allowed sales, design, and production teams to access and share data seamlessly. This improved interdepartmental collaboration and accelerated decision-making.

Modern Database Architecture

The database schema was redesigned to eliminate redundancies and support real-time data updates. This provided accurate insights into inventory, orders, and production timelines.

90%

faster issue resolution

The Results

automation of manual processes

reduction in survey processing times

survey participants handled by system

faster onboarding with an intuitive UI

- Enhanced collaboration across departments with centralized data access

- Improved client satisfaction with faster, reliable service

- Real-time insights into production timelines, order statuses, and inventory

- Eliminated manual processes reducing order processing & report generation time

Watch the complete video case study below!

Dan Bride

IT Director, Swatfame

Technology Stack

Share your business goals with technical experts

Sales and general inquires

sales@codedistrict.comCall us

+1 (703) 940-1971“Code District successfully launched our application on time. The team worked hard, adjusted to our schedule, and ensured our requests were turned around very quickly. They asked the right questions, used sound judgment, and made consistent progress, demonstrating strong technical skills and a driven attitude.”