How Emerging Technologies Are Solving Challenges in the Oil and Gas Sector

Contents:

-

Challenge 1: Legacy Systems Holding You Back

-

Challenge 2: The Cost of Technology

-

Challenge 3: Training and Upskilling Your Workforce

-

Challenge 4: Compliance and Security

-

Challenge 5: Data Management Woes

- The Bright Side: Benefits of Digital Transformation

-

Predictive Maintenance with Big Data

-

Predictive Maintenance with Big Data

-

Oil Production Optimization Software

-

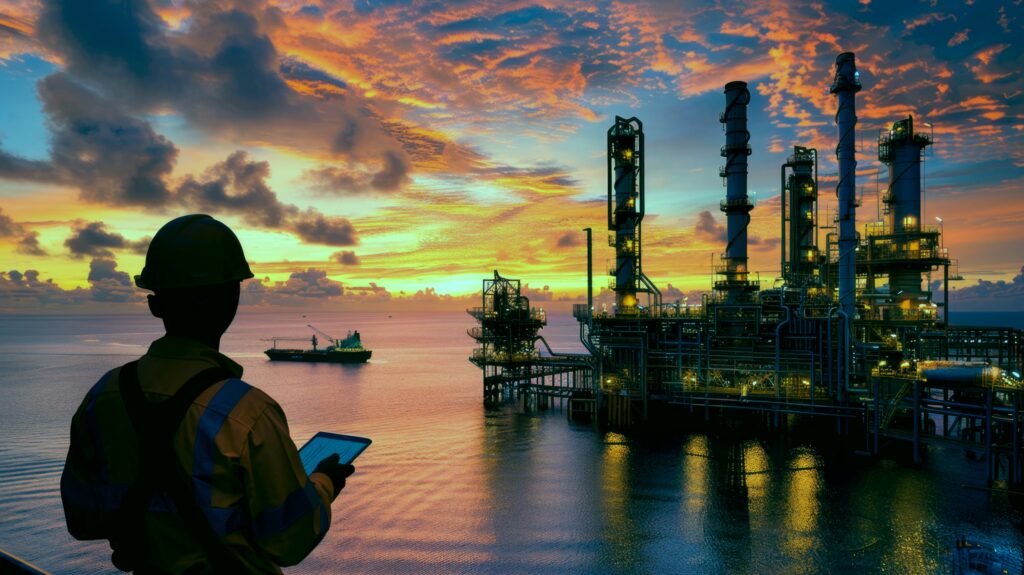

The Path Forward

The oil and gas industry is no stranger to volatility. Fluctuating prices, geopolitical shifts, and tightening regulations have become the norm. Yet, amidst these challenges, there’s a glimmer of opportunity: emerging technologies are transforming how companies operate, enabling greater efficiency, resilience, and sustainability.

But adopting these technologies is no small feat. Many organizations find themselves caught between the allure of transformation and the weight of entrenched legacy systems. To succeed, leaders must strike a delicate balance—embracing change while managing risk.

The Case for Digital Transformation

Digital transformation holds immense promise for the oil and gas sector, offering pathways to enhanced efficiency, safety, and profitability. However, the journey is fraught with challenges, as evidenced by a Boston Consulting Group (BCG) study revealing that only 30% of digital transformation initiatives meet or exceed their target value and result in sustainable change.

Why? The answer often lies in a combination of unclear objectives, resistance to change, and an inability to scale beyond pilot projects—a phenomenon often termed “pilot paralysis.” This hesitation isn’t unfounded. Oil and gas is an industry where margins are tight, and even small missteps can have significant financial or operational repercussions. But the cost of standing still is equally steep.

Why the Hesitation?

So, what’s causing companies to hesitate? Why is there such a significant gap between the potential of emerging technologies and their actual implementation? For many oil and gas companies, the answer lies in a combination of factors—cultural resistance, upfront costs, lack of expertise, and the perceived complexity of overhauling entrenched systems. There’s an understandable fear of disruption, especially when businesses have relied on the same technologies and processes for decades.

Additionally, oil and gas enterprises often operate in high-risk environments where even the smallest change can lead to major consequences, whether financial, operational, or environmental. The “if it’s not broken, don’t fix it” mentality is prevalent, and many fear that integrating new technologies could introduce vulnerabilities or create unintended consequences. But here’s the catch—by not moving forward with digitization, companies risk falling behind competitors and missing out on the immense potential that technological innovations offer.

Challenge 1: Legacy Systems Holding You Back

Many oil and gas companies are shackled by aging legacy systems. These dinosaurs of technology, once reliable, now pose a risk due to their lack of connectivity and visibility. The first step in digital transformation is confronting these outdated frameworks.

The financial implications of sticking with legacy systems can be staggering. For instance, operational inefficiencies can lead to production delays, resulting in significant revenue loss. Transitioning to cloud-based solutions can not only alleviate these issues but also provide scalability. Imagine running operations that can flexibly scale with market demands rather than being tied down by outdated infrastructure.

However, modernizing these systems can be daunting. Resistance from employees accustomed to legacy processes often complicates matters. The solution? Build a change advocate team or hire external consultants who can win over the skeptics and showcase early successes to build momentum.

A noteworthy example is Shell, which successfully transitioned from legacy systems to a unified digital framework, resulting in enhanced data analysis and decision-making capabilities. In 2019, Shell’s digitalization efforts contributed to cost reductions, production increases, and margin enhancements, collectively delivering more than $1 billion in value. These initiatives underscore Shell’s commitment to harnessing digital technologies to drive efficiency and maintain a competitive edge in the evolving energy landscape.

Challenge 2: The Cost of Technology

Investing in technology is like diving into a deep ocean—exciting but fraught with uncertainty. While upgrading to new digital solutions can modernize operations, the price tag can be daunting. Budget constraints often lead to postponed investments, which can be a recipe for disaster.

Take the cautionary tale of Southwest Airlines: aware of its outdated scheduling system, the airline chose to delay upgrades. The result? Over 15,000 flight cancellations during the 2022 holiday season, costing millions and tarnishing its brand reputation. This serves as a stark reminder: the cost of inaction can outweigh the expense of action.

However, financing solutions are emerging to alleviate the burden. Options like technology-as-a-service (TaaS) enable companies to pay for technology on a subscription basis, allowing for flexibility without a significant upfront investment. Companies can scale their technology use according to need, which is especially critical in an industry characterized by fluctuating demand.

Challenge 3: Training and Upskilling Your Workforce

Technology is only as good as the people using it. For digital transformation to take root, employees must be equipped with the skills needed to thrive in this new landscape. Training shouldn’t be a one-and-done affair; it requires ongoing support to adapt to new processes.

Digital adoption platforms (DAPs) like Code District can bridge this gap, providing in-app guidance that helps users navigate new systems effectively. This proactive approach not only enhances productivity but also smooths the transition to new technologies.

Consider the case of British Petroleum, which has implemented robust training programs focused on digital skills. They have partnered with educational institutions to ensure their workforce is ready for the digital future, leading to improved morale and retention rates. By investing in their people, BP has managed to maintain a competitive edge.

Challenge 4: Compliance and Security

As operations digitize, compliance and cybersecurity become paramount. With the oil and gas industry operating on a global scale, adhering to various regulations is crucial. Failing to do so can have catastrophic consequences.

The key is to develop comprehensive security policies that cover every aspect of operations. Proactive measures can prevent data breaches and ensure compliance with environmental regulations, safeguarding both reputation and resources.

Additionally, blockchain technology can enhance transparency and accountability in supply chain management, helping companies maintain compliance with regulatory requirements. By providing a tamper-proof ledger, blockchain helps mitigate risks associated with data manipulation and fraud.

A notable example is Chevron, which has adopted blockchain to improve supply chain transparency and ensure compliance with international regulations. Their initiative has significantly reduced audit times and enhanced accountability across their operations.

Challenge 5: Data Management Woes

In an era where data is the new oil, effective data management is crucial. However, many companies struggle with high data volumes and integration from diverse sources.

To tackle this, enterprises must invest in integrated data architectures that allow them to analyze and leverage data efficiently. This approach enhances decision-making capabilities, enabling companies to boost resilience and competitive advantage.

Cloud computing solutions, such as Microsoft Azure and Amazon Web Services (AWS), offer scalable storage and processing power, enabling companies to manage vast amounts of data seamlessly. For instance, TotalEnergies has adopted AWS to enhance their data analytics capabilities, leading to improved forecasting accuracy and operational efficiency.

The Bright Side: Benefits of Digital Transformation

To overcome these challenges, oil and gas companies need a clear and cohesive digital strategy. This means aligning business goals with technology investments and encouraging a culture that is open to change. Leadership must champion the shift and provide adequate training to ensure employees at all levels are equipped to handle new technologies.

But the strategy needs to go beyond simply adopting the latest tech. It requires a holistic view of how these technologies can integrate into existing operations without causing significant disruptions. The trick lies in finding the balance—leveraging the power of emerging technologies while carefully managing the transition from old to new systems, which includes:

1. Price Volatility Management

The oil and gas sector is notorious for its price fluctuations. However, digital tools equipped with AI capabilities can help firms predict and respond to these changes effectively. By using real-time data and predictive analytics, companies can model potential pricing scenarios and make informed strategic decisions.

It is statistically proven that companies that leverage AI for pricing strategies have seen an improvement in profit margins. This powerful technology is not just about cost-saving; it’s about strategically positioning oneself in a volatile market.

2. Change Management Support

Digital tools can streamline communication and project management, ensuring everyone has access to real-time data. Predictive analytics can even provide early warnings about market shifts, allowing leaders to proactively implement necessary changes.

For instance, Equinor employs data-driven decision-making tools that integrate insights from various departments, enhancing cross-functional collaboration. This holistic approach allows for quicker pivots in strategy, helping the company maintain its competitive edge.

3. Accelerating Carbon Reduction

Sustainability may seem like a daunting task for an industry rooted in fossil fuels, but digital innovation can pave the way for a greener future. Advanced sensors not only enhance operational efficiency but also contribute to significant environmental benefits by reducing emissions and identifying areas for improvement.

According to the World Economic Forum, implementing digital technologies in the oil and gas sector can reduce greenhouse gas emissions by up to 20%. This alignment with sustainability goals is increasingly critical, as stakeholders demand accountability and transparency from the industry.

Predictive Maintenance with Big Data

The flexibility of cloud computing allows oil and gas companies to store vast amounts of data and run complex analyses. This democratization of data access empowers decision-makers to identify opportunities for improvement and adapt to market demands swiftly.

For example, ExxonMobil uses cloud-based solutions to enhance its research and development processes, resulting in faster innovation cycles and improved product offerings. This approach underscores the importance of agility in today’s fast-paced market.

Predictive Maintenance with Big Data

Maintenance can make or break operations. Predictive algorithms analyze equipment conditions in real-time, allowing teams to identify issues before they escalate into costly failures. By implementing such technologies, companies can maintain a reliable output and minimize downtime.

BHP, one of the world’s largest mining companies, has successfully integrated predictive maintenance technologies into its operations, resulting in a 45% reduction in unplanned downtime. This significant improvement highlights the effectiveness of leveraging data for maintenance strategies.

Oil Production Optimization Software

Centralized enterprise software optimizes production processes, allowing for real-time data analysis and simulations. This technology not only maximizes profit but also ensures responsible sourcing practices that align with sustainability goals.

An example is Chevron’s use of digital twins—virtual replicas of physical assets—to optimize production strategies. By simulating various scenarios, Chevron has enhanced decision-making processes, ultimately leading to increased production efficiency and reduced operational costs.

The Path Forward

As the oil and gas industry continues to grapple with its challenges, emerging technologies offer a lifeline. Digital transformation is no longer a choice but an imperative for companies striving to remain relevant in a future shaped by technological innovation and evolving market demands.

Yet, the question isn’t whether to embrace these technologies, but rather how quickly and effectively companies can act. Organizations that delay risk being outpaced by competitors who are already leveraging advanced tools to enhance efficiency, reduce costs, and drive innovation.

For industry leaders, the time to act is now. Every delay represents not only a missed opportunity but also the potential erosion of competitive advantage. Embracing digital transformation is about more than survival; it’s about setting the standard for innovation and defining the future of the oil and gas sector. Those who do will not only navigate uncertainty but thrive, positioning themselves as leaders in an industry that remains critical to the global economy.